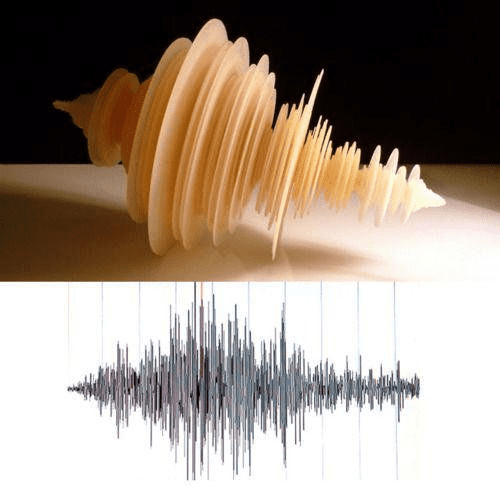

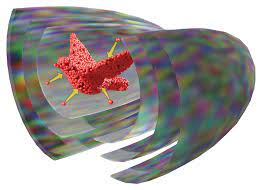

Amazing, these 3D objects were made with sound. This is a new method of 3D matter assembly has been developed by researchers from the Institute for Molecular Systems Engineering and Advanced Materials at Heidelberg University and the Micro, Nano and Molecular Systems Lab at the Max Planck Institute for Medical Research. Their design creates pressure fields using several acoustic holograms, which can be used to print solid particles, gel beads, and even living cells.

These outcomes pave the path for cutting-edge 3D cell culture methods with biomedical engineering applications. The journal Science Advances published the study’s findings. Utilizing functional or biological materials, additive manufacturing techniques such as 3D printing allow for the creation of complex parts. Traditional 3D printing, in which items are built one line or layer at a time, can be a tedious procedure. Researchers from Heidelberg and Tübingen have now shown how to construct a 3D shape out of smaller component parts in a single step. According to Kai Melde, a postdoc in the team and the study’s first author, “We were able to assemble microparticles into a three-dimensional object within a single shot utilizing shaped ultrasound.” “This has a lot of potential for bioprinting. Because of how sensitive the cells are to their surroundings during the procedure, “Peer Fischer, an academic at Heidelberg University, continues”.

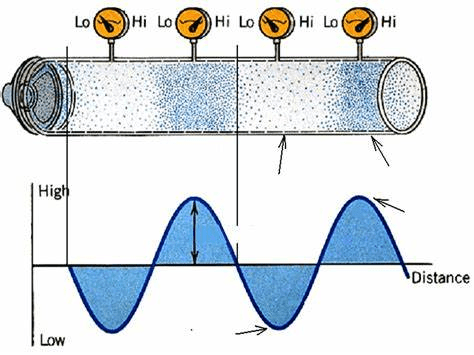

To explain further, anyone has been to a concert before and has experienced the pressure waves from a loudspeaker is aware that sound waves impose forces on matter. The wavelengths can be pushed below a millimeter into the microscopic realm using high-frequency ultrasound, which is audible to human ears and is employed by the researcher to influence incredibly small building pieces, including biological cells.

There has been prior research, where Peer Fischer and associates demonstrated how to create ultrasound using acoustic holograms, which are 3D-printed plates made to encode a particular sound field. They showed that materials may be assembled into two-dimensional patterns using those sound fields. The scientists developed a fabrication concept in light of this. The team was able to develop their idea further to arrive at 3D objects made with sound with their latest investigation. They gather floating particles and cells in the water and put them together to form three-dimensional forms. Additionally, the novel technique is applicable to a wide range of materials, including biological cells, hydrogel or glass beads, and other materials.

Conclusion

3D objects made with sound will become a thing in the future following this recent discovery. We are on the watch out for many applications of this even at industrial based levels. Hopefully, there won’t be a negative downside to this discovery.

Read More

Cure For Fatal Fungi Infections